SinoTrailers supplies low bed trailer and lowboy trailers for road transport of construction machines and equipment.

What is low bed trailer

Low bed trailer is a kind of semi-trailer that has a super low cargo platform, the platform is also called drop-deck. And the low bed part has no sidewalls. Rear-axle numbers could be 2-4 axles. Mainly specialized for transportation of crawler crane, excavator, crawler loader, bulldozer, railroad equipment, and other crawlers/tires equipment. Benefit from the low bed design, the trailer has high trafficability to go through bridge arc and tunnel, and lowers COG(center of gravity) of cargo.

Different types of lowboy trailer

- Classified by chassis design:

- Flatbed type, the whole trailer platform is flat, equipped with loading ramp at the rear side

- Lowbed type, the trailer body has a drop-deck which is lower than the front gooseneck and the rear wheel-set, due to the drop deck design, it always comes with a gooseneck, so it is also called low bed semi-trailer

- Hollow chassis frame type, the lowest height of the trailer’s rear part is the same as the diameter of tires, which means together with the trailer chassis, tires will bear the load directly when loading the cargos

- Classified by suspension:

- Mechanical spring suspension low loader

- Non-steer axle

- Steering axle lowbed, widely used in high carrying capacity trailers with more than 4 axles. Could manufacture 6 axles, 7 axles and above steerable trailers.

- Hydraulic pendulum axle lowboy, hydraulic platform trailer could be coupled with a low bed platform to transport oversize equipment over up to 200 tons

- Pneumatic(air bellow) suspension lowbed trailer

- Mechanical spring suspension low loader

- Classified by loading ways: please see below chapter

How to load cargos on top of lowbed trailers

- Rear ramp loading: Equipped with a fixed neck at the front and a climbing ramp at the rear of the trailer, no need procedure to detach neck, just put down the mechanical/hydraulic ramp then you can load and unload equipment directly. By this means construction machines need the strong ability to climb the high ramp. Loaded by a ramp at the rear side of the trailer, because of trailer wheels, the height of the rear side is higher, so the loading ramp should be very long then the machine able to climb on it. Also, the height of the rear loading ramp will increase risks during the loading and unloading process.

- Side-loading: This method requires a wide-open yard for the loading, which is hard to achieve in most scenarios. If goods are on a platform, and the height of the platform is near the height of the trailer’s deck, this would be a good solution for loading.

- Front-loading: With detachable(removable) gooseneck, when removing the neck from a low bed trailer, the slope design of the front deck enables construction machines to climb up/down freely. This is the most efficient way for cargos loading and unloading, this type of trailer can be divided into two categories:

The steel structure design of lowboy

Chassis frame design: The chassis frame is the main loading steel structure of the lowboy trailer, so the design of it will be a key part of its usability. To make sure a safe transport of the cargo machines, the design of the loading platform is to make it as low as possible, that is why the chassis frame is drop-deck design.

- Flatbed type, cargo platform is flat and on top of tires, to transport steel material, logs, and oversize equipment

- Gooseneck type also called stair type trailer, cargo platform is lower than the top surface of gooseneck

- Low drop-deck type, gooseneck, and rear part of the trailer are both higher than the middle part of the trailer, which makes loading of goods in a very low position

- Future trend of chassis design is seeking lightweight, and high strength and rigidity

Landing gear

- Landing legs are installed in the front of the lowbed trailer body, the function is to support the trailer so that tractor can be connected or disconnected easily

- The landing gear is extended and retracted by manual operation, via lifting structure embedded in it

- Reliable for maintaining the trailer’s level when it is disconnected from the prime mover

- Simple design, but strong and rigid enough to adjust height rapidly

- Bearing the weight of landing gears are no more than 50% of the trailer’s total mass

- The safety factor is between 1.1 to 1.3

Features of low bed trailers

- The mechanical or hydraulic climbing ramp is an option for easy loading and unloading

- Lower height (hydraulic and air suspension be able to adjust height)

- Detachable gooseneck is an option

- Small turning radius, up to 55° steering angle

- Both automatically and manually all wheels steering

- Drop deck minimize the trailer’s platform height, increase trafficability and stability for over height cargo

- Side bracket is an option(for increase overall width), removable and swinging

- The top surface of the loading platform is wood to anti-skidding. Optional diamond plate.

Consists of low bed trailer

- Chassis fame

- Side beam structure, the longitudinal beam is molding I shape steel or welded I shape steel

- The frame shape is stair shape or drop-deck shape, to minimize the height

- The latitudinal beam is pressed steel

- Suspension

- Including tires, axle, brake, and rim

- Axle and axle head are high-quality steel

- Axle body is a rectangular section

- Most lowbed trailers using mechanical spring suspension, hydraulic and pneumatic suspension are options for special cargos

- Landing gear

- Double speed type

- Electrical system

- Single wire system, negative ground, voltage 24

- Rear lamps, steering lamps, outline marker lamps, side marker lamps, reflex reflector, rear fog lamp, license plate lamp

- Brake system

- Emergency relay valve, air reservoir, spring energy reservoir chamber

- Smooth and rapid brake

- Good cooling performance

- Trailer’s brake system is coordinated with that of the tractor prime mover, braking order is front wheels of the tractor, wheels of the trailer then rear wheels of the tractor

- Dual-chamber brakes the trailer in parking mode when brake air pipe is disconnected with that the tractor

- Double air-lines brake system. One line is a braking line, which is connected to the tractor’s air reservoir, it’s charging air to the trailer’s reservoir all the time. Another line is the controlling line, which is connected to the tractor’s dual-chamber. There is no air in the controlling line in common situation, when the driver brakes tractor, compressed air from the tractor’s reservoir will be sent to the emergency valve of the trailer, then the emergency valve will release compressed air from trailer’s reservoir to trailer’s brake chamber. The advantage of the dual-line braking system can charge the reservoir all the time when climbing down from a slope, if leakage happens and the pressure is lower than the stipulated air pressure, the emergency can stop the trailer automatically

- Brake system is able to park the trailer with a full load on a %16 slope road

- Brake time between brake of the prime mover and brake of lowboy’s last axle is less than 0.2s

- Leakproofness: When air reservoir pressure reaches 637kPa-735kPa, in non-brake condition, air pressure dropping speed is not more than 10kPa/10min. In brake condition, air pressure dropping speed is not more than 10kPa/6min

- Braking ways of the emergency valve:

- Charging and safety brake(feedback brake). Normally the trailer’s reservoir is big compare to that of the tractor, so charing the air will take a while. When the air pressure is lower, for safety reason, the trailer is braked until air pressure is high enough to realize working brake(see below)

- Working brake, when the braking pedal is stepped, compressed air will function the brake. When the pedal is released, braking released too

- Emergency brake also called air cutting-off brake

- Loading ramps:

- Front-loading ramp

- Hydraulic rear loading ramp

- Mechanical rear loading ramp

- Removable rear loading ramp

Specifications of lowboy

- Loading capacity: 30-150 tons

- Length and width dimensions available custom made

- Heavy duty and extra durability designed I beam

- High tensile steel Q345B(or above) welded by automatic submerged-arc process

- Top flange 14mm, middle flange 6mm, bottom flange 16mm, width 140mm

- Axle numbers: 2 axles, 3 axles, 4 axles

- Axle brands: BPW, L1, YORK or FUWA

- Option for more axles than 4 if choose the hydraulic axle

- Suspension: mechanical, hydraulic or air suspension

- Leaf spring: 8 pieces

- Ramp: mechanical spring or hydraulic lifting ramp

- Traction pin: 2″ bolt-in

- Spare tire: one set spare tire with tire carrier

- Braking system: WABCO RE 6 ABS relay valve, T30/30 spring brake chamber, 45L air tank

- Lights: 24 volts, 7 pins socket. Traffic warning signs

- Heavy-duty landing gear: two speeds, manual operating

- Painting: complete chassis sandblasting to clean rust, 1 coat of anticorrosive prime, 2 coats of final paint

- Accessories: one standard toolbox

Maintenance of lowboy

- Tires inspection

- Check the pressure of tires every month, refill air if the pressure lower than standard pressure

- The pressure cannot be very high which may impact driving safety. If the tire has a crack, it should be replaced accordingly

- Battery maintenance

- Check if the battery is fixed up, battery liquid has to be in the middle position

- Fill with electrolyte or distilled water if the liquid is short

- Remain contacts of positive and negative electrode are fine

- Keep the battery dry and clean

- Take electrodes off if put the lowbed in storage for a long time

- Recharge the battery if it’s low

- Long-term storage

- Avoid sunshine, damp

- The storage room has ventilating air, fire equipment

- Regular maintenance according to the manual

- Anti-rust process before long time storage

Types of dropdeck

Extendable dropdeck: could be extended in longitudinal and latitudinal directions which means the length and width can be increased to suits oversized cargos. This type of drop-deck normally works with modular trailer.

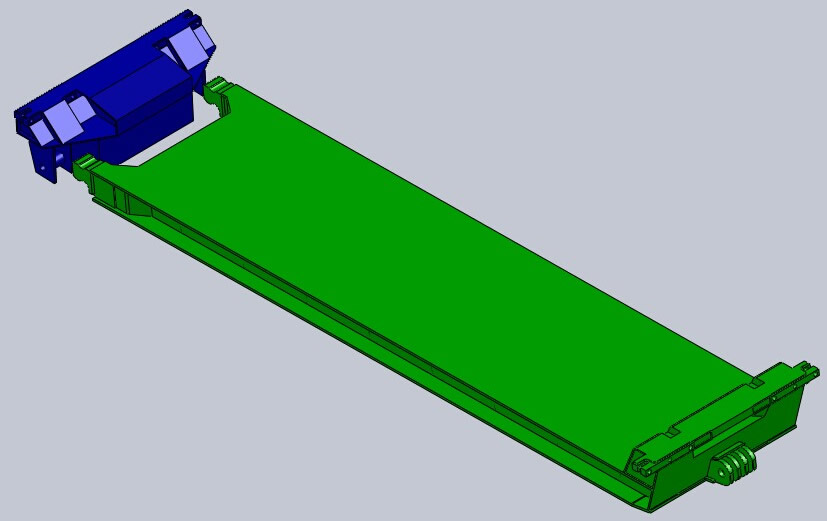

Similar to RGN trailer, the drop-deck can be removed from the trailer to enable fast loading and unloading. The above low bed is designed for excavators and other construction machines equipped with crawler.

Loading ramp of low bed trailer

Mechanical ramp is budget friendly

Could be mechanical or hydraulic folding modes.

Current market needs more front-loading ramps due to its low loading height and shallow slope.

Hydraulic ramp low bed trailer

The above ultra-low lowbed trailer has 4 axles in 2 lines, with hydraulic folding ramps, both ramps can be adjusted sideways for different widths construction machines. All wheels are steerable, and the spare tire rack is on top of the gooseneck. There is an electronic control panel on the trailer’s neck.

Want to lower overall traveling height more than mechanical suspension lowbed trailers? You need a hydraulic lowbed trailer with a girder beam set or a drop-deck, adjustable height makes your oversize cargo can be transported several millimeters off the ground.