Wind energy resource is rich in mountain regions; many wind power plants are in those areas. SinoTrailers wind blade adapter can incline the rotor blade to reach 70°. With hydraulic cylinder control and slew bearing, the wind blade’s maximum rotation angle could up to ±110°. During transportation in mountain roads, the adapter can avoid the cliff, woods, and electric wire via operations of the incline the blade to extent degrees, or rotate and swing the blade. Using a wind blade adapter will save you cost on obstacle removal.

Why we need to transport the windmill turbine equipment to the top of the mountain

Mountain wind farm is the best place for developing the wind power industry onshore, regardless of its scale or wind resource conditions. Mountain wind resources are adequate. The massive base scheme is conducive to reduce unit cost and reduce electricity cost, which is the inevitable direction of onshore windmill power development.

With the development of wind energy equipment, there is no doubt that reducing cost and increasing efficiency is the only way out. According to industry experts’ research and developers’ actual development path, the future onshore wind power can be divided into large base, decentralized, and local regional centralized. No matter which category, equipment manufacturers bear the brunt of the most significant pressure and responsibility. According to the medium and long-term carbon neutrality goals, wind power also carries a considerable energy transformation mission.

So far, the blade of the windmill turbine is about 70 meters long and weighs 20 tons. Because most wind turbines are on the top of the mountain, it is challenging to transport these massive objects to the mountain’s top. As the adapter with the blade, it can be no side slip and other conditions. Therefore, the requirements of the road surface to transport the windmill blade can not be soft. It must be hard enough to support the wind blade adapter trailer.

Windmill blade adapter trailer

The windmill blade adapter trailer has two parts: the superior design low bed trailer and the unique design adapter.

About the trailer, it is an enhanced version of a conventional low bed trailer.

Due to the adapter has the function of lifting, we also call this type of trailer blade lifting trailer. This model is suitable for mountain transportation, and the cost to purchase such a blade lifting trailer is far less than the cost of road reconstruction. The adapter trailer is designed as a steering axle trailer, which can realize:

(1) blade lifting movement: when the oil cylinder is compressed, the blade is lifted, and the blade lifting frame shrinks to the center of the rotating axis, and the movement track of the lifting center of gravity is always near the rotating axis, effectively avoiding the instability during transportation, and the lifting angle is within the range of 0 ~ 60 degrees.

(2) Rotation movement: the rotating oil cylinder drives the blade on the rotating bracket to deflect left and right along the center of the semi-trailer. The designed deflection angle is ± 45 ° (calculated from the landing in front of the wind blade tip).

(3) The blade lifting, rotating, and cooperating with the hydraulic steering of the rear wheel of the vehicle plate drives the rotating device to move horizontally. The blade can avoid obstacles to the greatest extent in the transportation process, reduce the work of road reconstruction, shorten the construction period, and reduce the investment. This type of blade lifting trailer has a small turning radius, less occupied road width, and convenient reversing. It is especially suitable for transporting wind turbine blades of various specifications.

Feature of extendable in width

This feature is to increase the stability of the trailer when loaded with the blade. When the blade is rotating, sometimes the COG is out of the trailer. If we expand the width of the trailer, the stability will be on a pretty high level.

The width of the trailer is widening from 3,400mm to 4,400mm. The widening range is 1,000mm.

Feature of sideways moving

Another critical function of the width widening system is the sideways moving function. When traveling through sharp bends, the specialized low bed trailer could slowly move sideways by its power pack. This function helps the blade adaptor trailer can pass the sharp turns rapidly.

For the blade adaptor, please see below windmill adaptor chapter.

The two cylinders can adjust the angle of the blade, theoretically, the angle is ranging from 0 to 60 degrees.

How to operate the windmill blade adapter trailer

To transport 70 meters long and 20 tons of wind turbine blade to the top of the mountain. Not only drivers but also team commanders, adaptor commanders, transport team leaders, and adaptor operators. Only their tacit cooperation can smoothly send the windmill blade to the top of the mountain.

Wind blade adapter trailer commander

Responsible for the fleet’s blade transportation’s safety command, the main difficulties are the turns and the mountain. If you encounter obstacles and turns during driving, you should command the driver and operator in time.

Adapter trailer driver

During driving, once the obstacles are in front of them, they should communicate in time. The staff at the back of the team shall immediately cooperate with the driver after understanding the situation.

Adaptor commander

Mainly responsible for blade’s angle position. When the windmill adapter trailer is turning, the blades can move up and down together with the adaptor, left and right, avoiding obstacles that may collide.

Adapter operator

Follow the command of the adapter commander, react quickly, and control the direction of the blade.

Trailer operator

In addition to the adapter operator, there is a particular type of work – steering operator, responsible for steering 32 wheels in 4 lines at the rear of the windmill adapter trailer.

Why the blade adaptor trailer has to be safe and reliable

After the wind power equipment is transported to the wind power site, if the wind farm is on the mountain, the mountainous area’s transportation operation has great hidden danger and high risk of all kinds of unforeseen adverse factors. That is why we have to keep the windmill blade adapter’s safety and reliability as the priority.

We should take emergency protection measures for the special conditions of storm weather in mountain areas.

Wind blade adapter

With the blade’s adjustable angle function, the adaptor operator could change the angle position to adapt to limit road space on mountains.

Self-balancing counterweight system

Automatically adjustable weight balance to ensure stability.

Self-balancing counterweight system makes sure total balance during transport when a trailer loaded with adapter and wind blade, even encounter intense winds weather. The system can ensure the overall balance of the blade adapter trailer.

The system is pretty useful when transport different types of blades. Also, while the loading blade’s angles changed, the sliding adapter could change its location to make sure the COG of the trailer and blade is in a safe range.

With this design, there is no need to put counterweights on the adaptor.

Weighing system

A newly designed weighing system has four weighing points on each corner of the adaptor, displaying how much the weight and pressure the four points to bear to make sure the blade’s COG is in a safe position and guarantees safety while climbing the mountain road.

Wind mill blade connecting flange

The connecting flange is replaceable for other types of windmill blades. Using bolts to fix the wind blade to the flange base so that the blade and the base are firmly integrated. During transportation, the blade can move up and down, left and right easily to avoid obstacles.

Hydraulic landing leg

Ensure safety when wind adapter trailers pass through severe road conditions

Slew bearing

The hydraulic motor inside drives the big gear to rotate the whole adapter.

Power pack

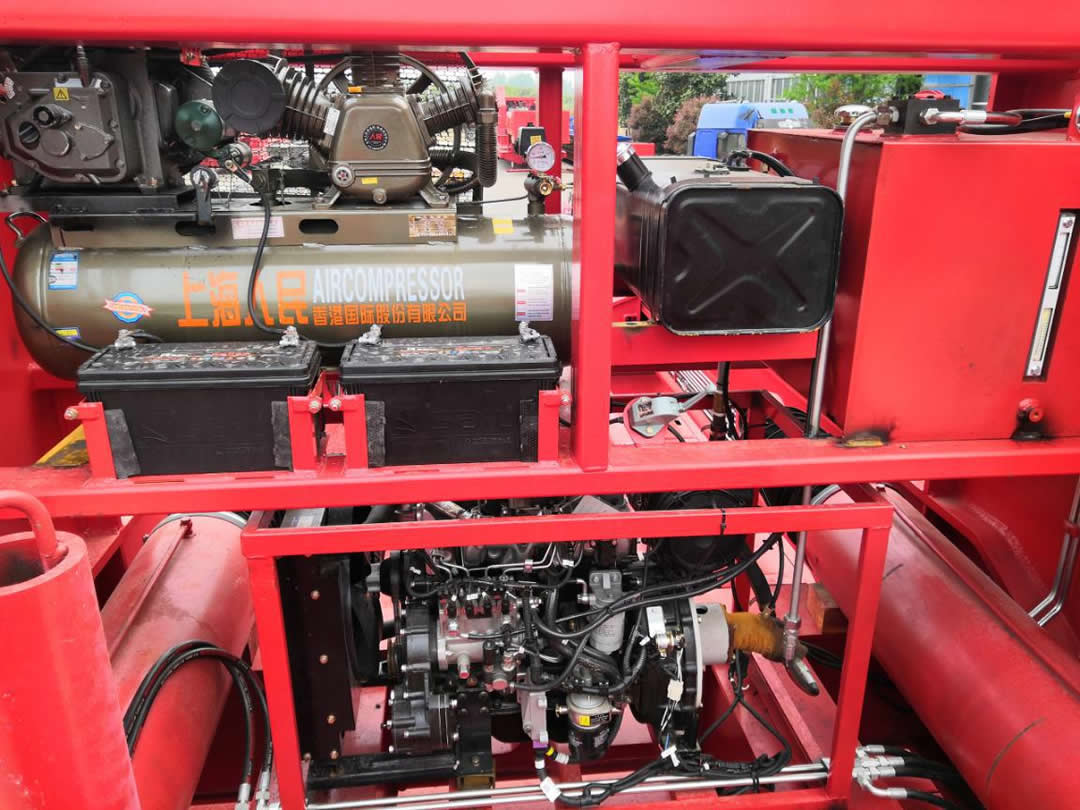

The diesel engine and hydraulic pump in the power pack supply the power sources for the windmill blade adapter. Besides that, the pack has an air compressor, battery, hydraulic oil tank, and fuel tank.

The wind blade adapter is available with the trailer you have. You can have a one-stop package, including the most suitable low bed trailers, which have the shortest total length(small turning radius) to adapt to remote areas’ road conditions.

The rotor blade adapter is compatible with low deck trailer, heavy-duty modular trailers, and SPMT module. Because the blade is over-length, balance weight is a must-have to keep the whole trailer’s balance. Sliding rail helps to move balance weight quickly.

If you have existing modular trailers and SPMT from Goldhofer or Scheuerle, we can make our adaptor to match your equipment.